Industrial automation

Our safety sensors are used wherever automated processes can pose a risk to people. They enable reliable access detection in a wide range of applications – especially in safety-critical areas around machines, CNC systems and transfer lines. They also provide effective anti-trap protection when safeguarding linear closing edges and thus make a decisive contribution to accident prevention in industrial automation.

Safety for machining centers with movable gantries

Maximum speeds mean increased efficiency of machining centers, whereby the freedom of movement of the operating personnel for loading the machine should always be taken into account. Our SENTIR safety contact bumpers allow the machining center to continue working at reduced speed as soon as the safety distance is undershot while still providing 100% personal protection. An immediate stop signal is only given in the event of direct contact in the acute danger zone, of course taking into account the overtravel of the gantry and the permissible forces.

The use of SENTIR safety contact mats from ASO as multi-zone area guarding also ensures process continuity despite entering the danger zone. The milling, pressing, turning or welding center works on one side of the machine table, while the skilled worker can remove finished parts on the other side of the machine table – all at full speed. If the safety area in the middle is entered, the speed of the gantry is reduced, while in the danger zone an immediate stop is triggered when the mat is stepped on. Depending on the environment, additional protective enclosures can be dispensed with by using one of the two tactile sensors, allowing maximum use of the area. The SENTIR sensors are unaffected by chips, vibrations or other environmental influences, just like the complementary ELMON relay evaluation unit series, which switches off safely in the event of actuation.

Safety for closed machining centers

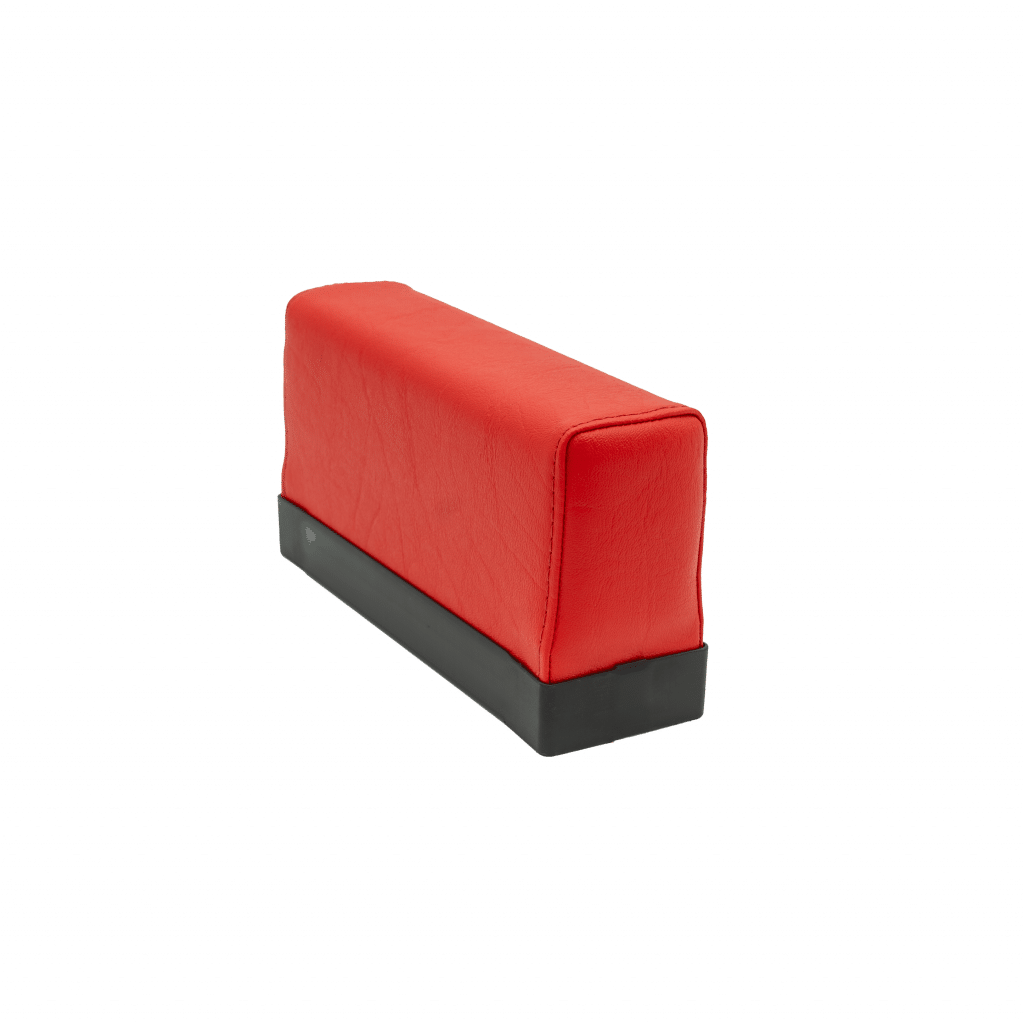

Automatically operated doors and flaps on machining centers can save time by opening and closing quickly so that workpiece processing takes up as much of the work process as possible. The potential crushing edges of the doors, which open faster, are protected by our SENTIR safety contact edges, which trigger an immediate stop or reversal when actuated.

The patented double chamber system protects the internal switching chamber from external mechanical influences. Radii or kink angles for precise integration into the door and machine design are a matter of course, as are robust materials with high resistance to a wide range of influences. In addition to a very broad portfolio of different profile dimensions, in-house development and extrusion can create a profile tailored to individual requirements, e.g. translucent material can be used for illumination using LED strips.

Our SENTIR safety contact mats protect against dangerous situations in front of or inside the machine in connection with moving parts. The SENTIR mat thus ensures presence detection of the worker in a variety of applications and areas. Whether access protection or ensuring freedom of movement of the milling, drilling or spraying head within the machine, a dangerous movement is prevented by the contact mat.